Microencapsulation technology is applied in the field of plant extract food raw materials. By encapsulating active ingredients in micrometer sized capsules, it brings multidimensional innovation to the development of traditional plant extracts. It can make the active ingredients have sustained release or targeted properties, improve bioavailability, reduce dosage and toxicity in non target areas, and greatly improve drug efficacy and safety. This is mainly reflected in the following aspects:

Providing better anti degradation protection, microcapsules can isolate external factors such as oxygen, light, humidity, etc., preventing the decomposition of easily oxidizable components such as plant polyphenols and volatile oils, and extending product shelf life.

Some heat sensitive ingredients (such as enzymes and vitamins) are easy to inactivate during processing. After embedding, microcapsules can withstand high temperature treatment (such as spray drying and sterilization) to provide their tolerance.

Enhanced solubility: Microcapsules can improve the dispersibility of lipophilic components (such as curcumin and lycopene) in water through nanomaterialization or emulsification techniques, promoting intestinal absorption.

Slow release and controlled release: By selecting different capsule materials (such as chitosan, PLGA), timed and quantitative release of extract components can be achieved, reducing metabolic losses and allowing for more absorption and utilization.

Organ targeting: For example, encapsulating plant anti-cancer ingredients with pH sensitive polymers to release them in the tumor microenvironment and reduce toxicity to normal cells- Mucosal adhesion: When administered through the nasal or oral cavity, microcapsules can adhere to the mucosal surface, prolonging the local action time (such as using menthol for pain relief).

Covering the bad flavor: after embedding the bitter ingredients (such as berberine, tea polyphenols, Ashwagandha) in the microencapsulation technology, the taste has been greatly improved and the bitterness has been eliminated.

Enhanced efficacy synergy: a variety of plant extracts (such as curcumin+Ashwagandha) are encapsulated in the same microcapsule, and the drug effects are superimposed through the slow release sequence.

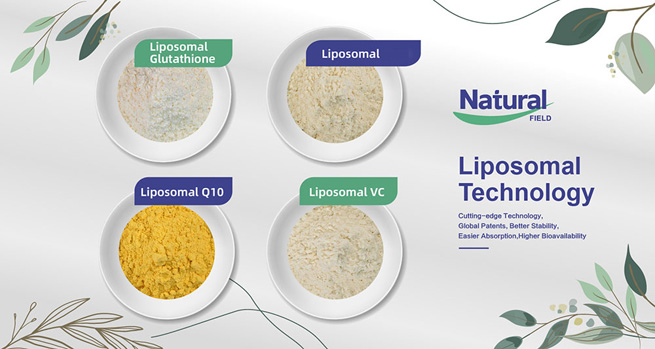

New carrier development: such as liposomes, solid lipid nanoparticles, etc., plant extracts can be made into injections, transdermal patches, or inhalants- Intelligent response system: Temperature sensitive or photosensitive microcapsules can be released under specific conditions, suitable for personalized medicine (such as thermal therapy triggering drug release).

Natural carrier application: Using renewable materials such as sodium alginate and starch to replace synthetic polymers and reduce environmental burden.

Green production process: Microfluidic technology can accurately control microcapsule preparation, reducing solvent usage and energy consumption. Typical application scenarios

Food industry: Co encapsulation of probiotics and plant polyphenols to enhance intestinal colonization ability.

Cosmetics: Retinol microcapsule essence (improve light stability and reduce skin irritation).

Cost control: Complex microcapsule processes may increase production costs, and further optimization of large-scale preparation techniques is needed.

Intelligent direction: Combining artificial intelligence to predict microcapsule release behavior and promote the development of personalized formulations. Microcapsule technology is evolving from a single protective function to multifunctional integration, opening up new paths for the efficient utilization of plant extracts, especially in the fields of precision medicine and green manufacturing, with enormous potential.

Xi'an Natural Field Bio Technique Co., Ltd. continuously invests in the research and development of food raw materials, and the application of new technologies such as microencapsulation, liposome technology, and co loaded liposome technology provides more possibilities for product development in the health food raw material industry. Natural Field has always been committed to the supply and solutions of high-quality health raw materials. If you are interested in high-tech food raw materials, please continue to follow our website.

English

English français

français Deutsch

Deutsch Español

Español русский

русский português

português